Shafting integrated service refers to technical services such as laser detection, on-site machining and compliance adjustment, so that the original or un calibrated shafting can meet the requirements of shafting calculation, and the stress of each shaft section and all bearing loads in shafting are within the allowable range or have reasonable values, so that the shafting can operate normally and reliably.

A 60000DWT semi submersible ship with twin engines and twin propellers was manufactured by the customer. Before the trial voyage, when the motor car was on the wharf, the stern bearings on both sides were hot, and the position of the main engine was fixed, which could not be adjusted. The business order has been confirmed and the shipping date is very tight.

Determine the reason of shafting change, readjust shafting to meet the requirements of normal use.

The maximum submergence of the semi submersible is 22 meters, the shafting of different draughts changes greatly, the hull load changes greatly, and the ship type is special.

The time is tight, the shafting adjustment is complex, and each link needs to be closely linked.

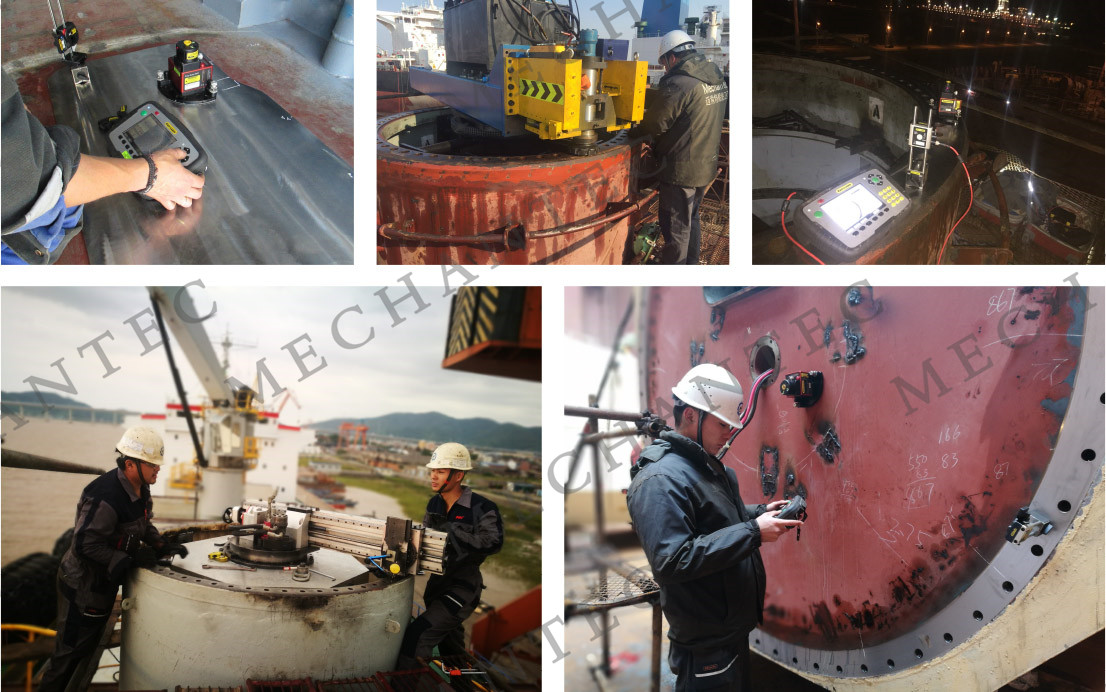

Construction equipment: bb5000 boring machine, hydraulic power unit, load test tools, hollow oil roof, etc.

Measuring equipment: prufu laser alignment instrument, outer diameter ruler, inner diameter ruler, finish meter, dial indicator, oil pressure gauge, etc.

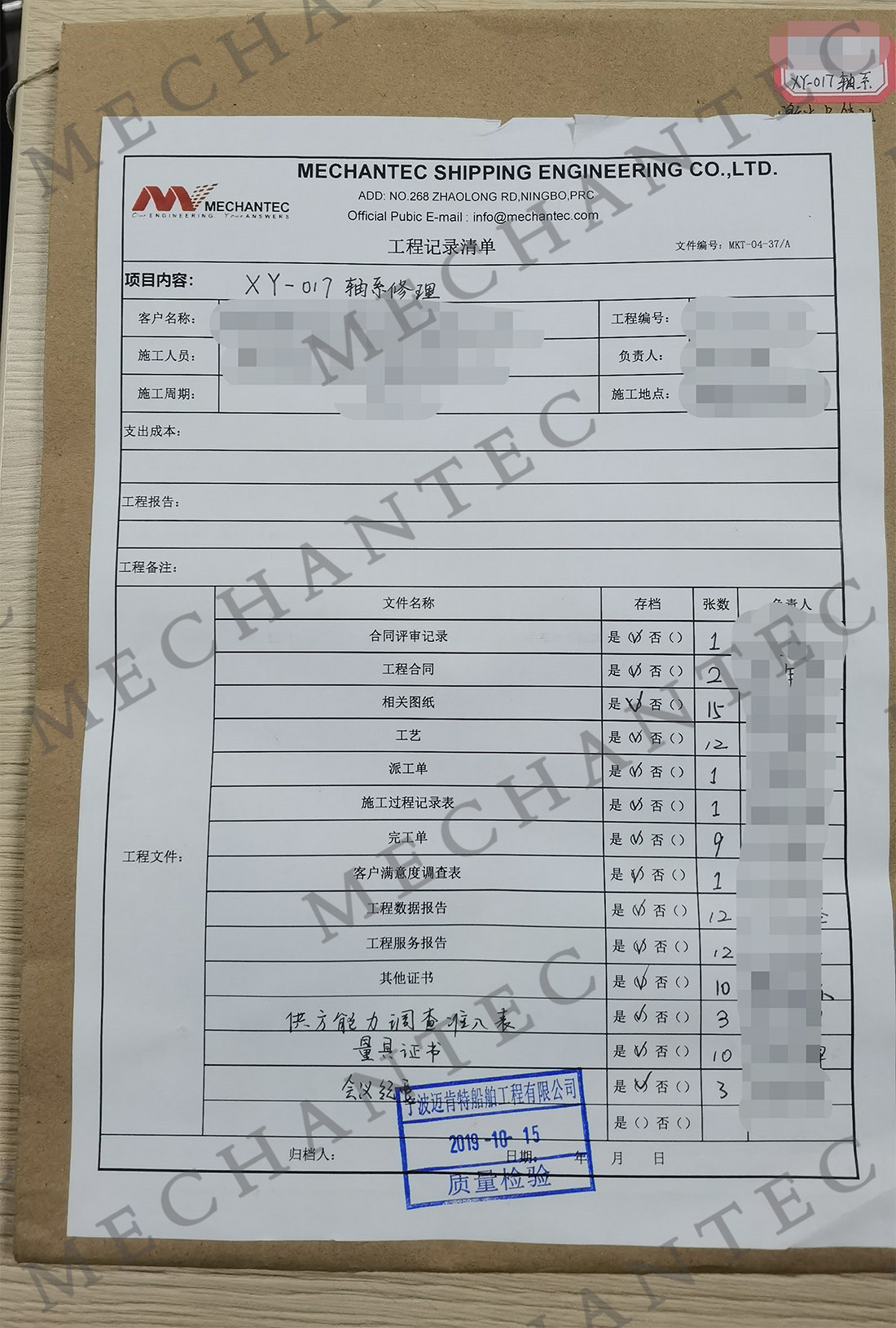

After the customer's request, our team will have technical communication with the shipyard and the shipowner at the first time to determine the specific project content and put forward the optimal solution.

McKinsey team participates in no damage drilling of flywheel end coupling bolts

The shipyard organizes the ship owner, ship inspection team, mckent team and ship design institute to recheck, calculate and analyze the laser detection results, and determine that the change of shafting centerline is caused by hull deformation. According to the measurement results, the professional shafting calculation is carried out, and the new shafting calculation sheet is determined again, which is reviewed by the drawing review center. According to the requirements of the new calculation sheet, systematic technical services are provided for the existing problems of the ship.

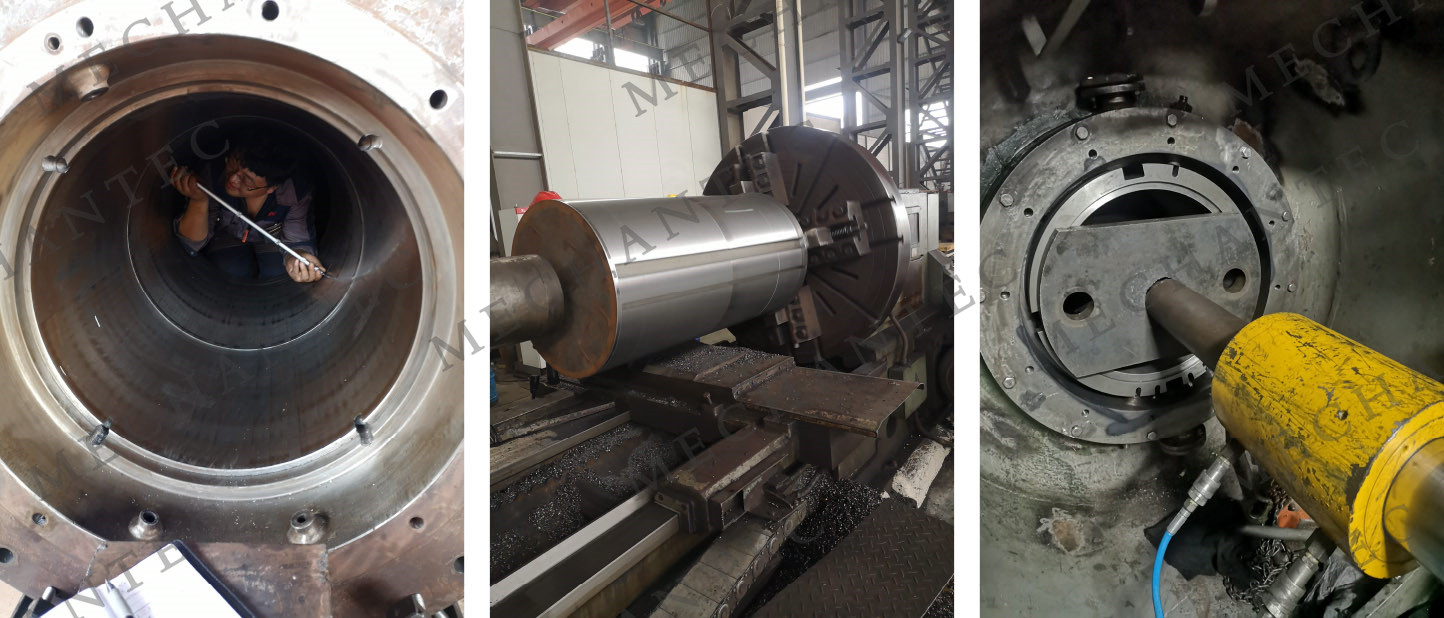

The stern shaft is repaired by laser cladding

Pouring and processing of Babbitt alloy for intermediate bearing seat

Due to the limitation of epoxy thickness, the stern bearing pedestal can not meet the requirements of the new shafting calculation sheet after readjustment to the limit. Therefore, the axial problem is solved by eccentric boring of bearing pedestal. After machining, the cylindricity of bearing seat hole is ≤ 0.05mm, and the finish is ≤ RA 1.6 μm

The dimension tolerance of the new bearing body is within 0.05mm after processing. During the press fitting process, the pressure rises steadily, and the final press fitting pressure meets the requirements of ship inspection.

Our team participated in the boring of flywheel end coupling. After machining, the hole cylindricity ≤ 0.02mm, finish ≤ RA 0.8 μ m, verticality ≤ 0.05mm.

After the adjustment, under different draughts, the load of each bearing is within a reasonable range, the blue oil detection of the shaft section is qualified, and the value of the crank gear in the main engine meets the requirements of the description of the main engine.

After the completion of the project, the ship owner, shipyard and ship inspection gave a high evaluation. After a year of loading test, the customer said that the shafting was running well without any abnormality.